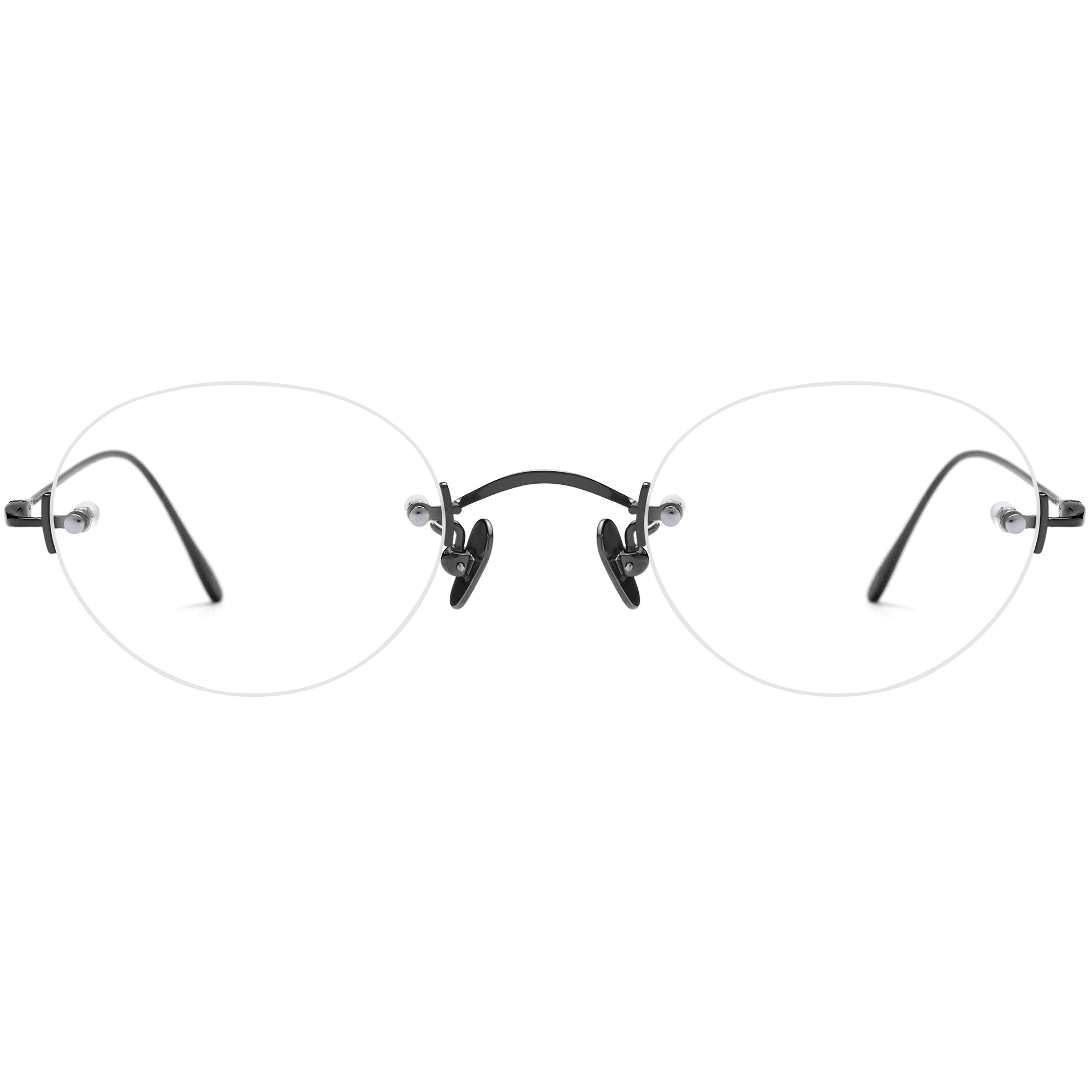

Lens Mounting & Frame Design

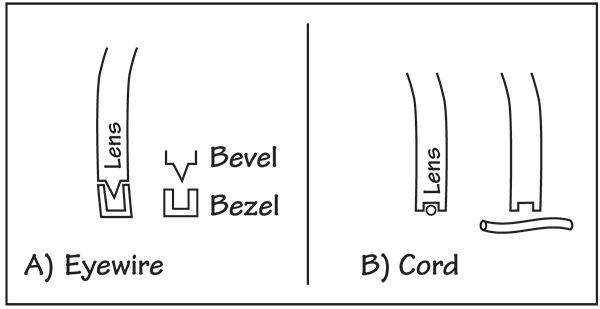

Metal frames are usually “full eyewires,” which means they have a solid metal band that surrounds the entire lens. The lens is held in place in a groove in the eyewire, which is tightened down around the lens with a screw. The technical term for the lens retention method is “bevel – bezel.” The lens edge is cut with a bevel, or convex edge, which fits inside the eyewire bezel, which is a concave-shaped groove.

Plastic frames are also usually “full eyewires,” which means they have a plastic band surrounding the entire lens. The lens is held in place by cutting the lens a little larger than the eyewire opening, and then snapping the lens in place,using the flexible properties of the plastic to hold the lens. It is also a bevel-bezel method.

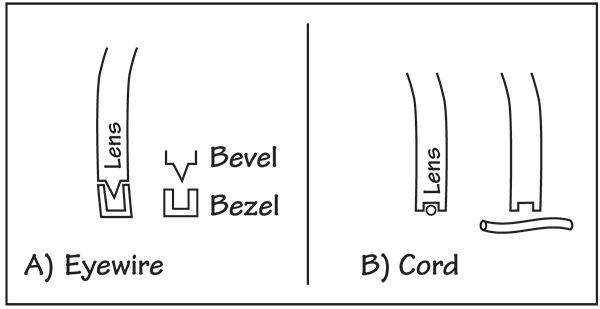

The lens is held in place by the tension the string places on the lens and by a tongue along the eyewire that catches the groove in the lens. These frames are reliable, and have been around for decades now. Adjustments can be tricky to make without breaking the string. However, restrings are quite easy. The actual mounting of the string is fairly consistent industry-wide, but there are some unique styles which require special attention.

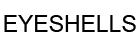

Another alternative to full eyewires is the three-piece mount, which is also called a rimless mount, or drill mount. These glasses are created by attaching the two temples independently, and then attaching a bridge directly to the lenses through holes that have been drilled through them. In three-piece mounts, the “bridge” will contain the guard arms, nose pads, bridge, and attachment points as one complete piece. Three-piece mounts are in fashion now, and because of modern minimalist designs and modern materials, they make some of the best glasses ever created.

Note: Either polycarbonate, Trivex or hi-index materials MUST be used in the manufacturing of drill mounts, or the lenses will crack. CR-39 or mid-index plastics may not be used. Some labs will even refuse some high-index materials so you will need to check.

Modern three-piece mountings are assembled using plastic sleeves and pressure fittings, thus eliminating the use of screws. In the past, screws or nut-and-bolt mountings were used. They were a very poor choice for eyewear construction. Avoid creating an unhappy customer: do not sell nut-and-bolt mounting frames. They will only come back to haunt you! Don’t say I didn’t warn you.

I mean does this really look like a good idea to you?

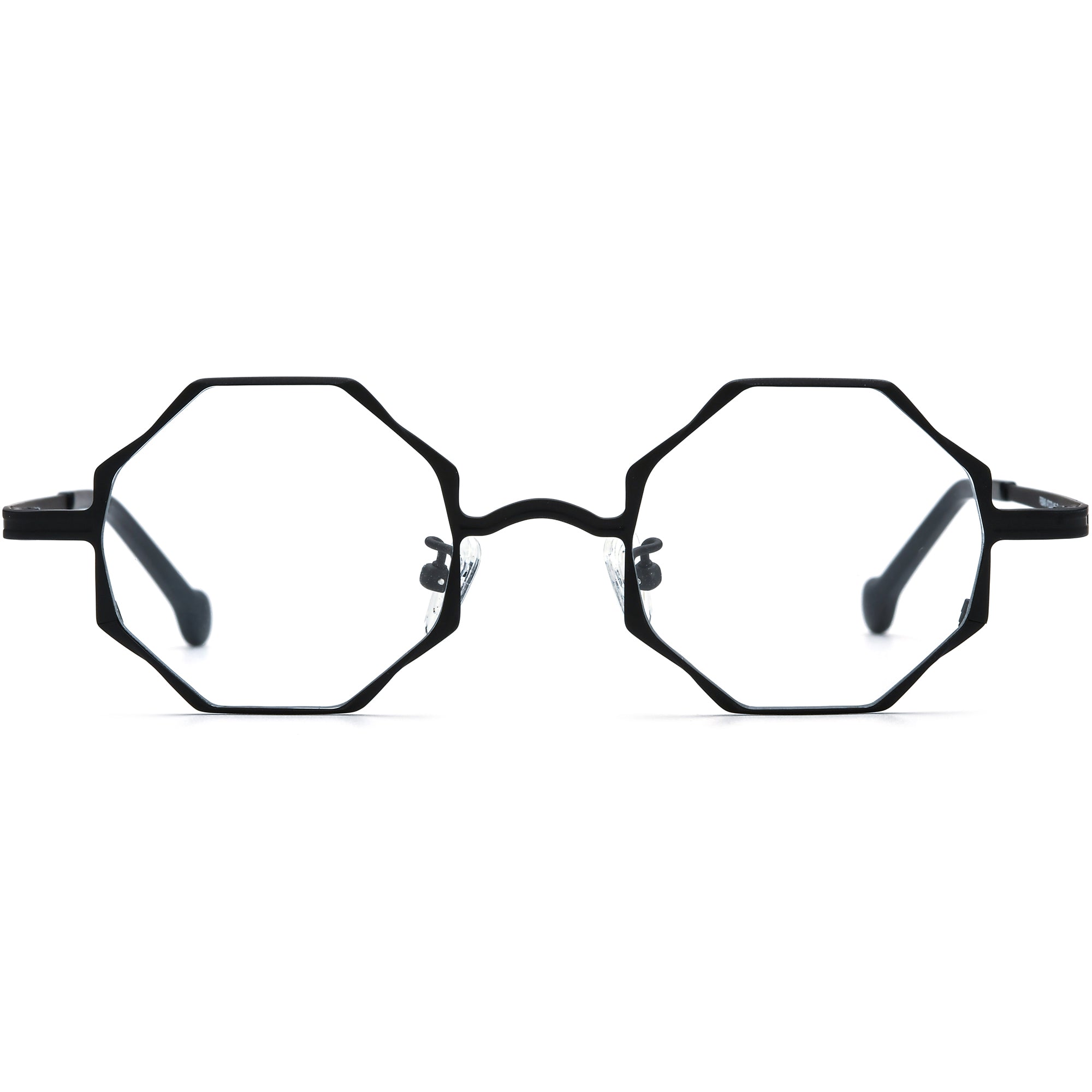

In addition to the common mounting techniques, screw closure, plastic retention and drilled pressure mounting you will come across others. The industry is always trying to come up with something different.

SwissFlex is a line of frames with snap on flex-plastic parts, distinct coloring and extreme light weight. I’ve had a pair or two along the way and was quite happy with them. Notice the neat appearance, lack of a mounting bushing and no need for two posts to keep the mount from moving.

However they use a proprietary adhesive mount which can only be done by a handful of labs in the US.

I’d suggest Luzerne Optical Labs in Pennsylvania which is a SwissFlex approved lab.

You may also find razor-thin eyewires usually in titanium that screw, “snap” or lock in place using a semi-rimless groove.

When properly assembled all these frames are both beautiful and functional, but, can create problems when mounting lenses in-house without the proper tools and experience. The image above is actually my own frame from MODO.

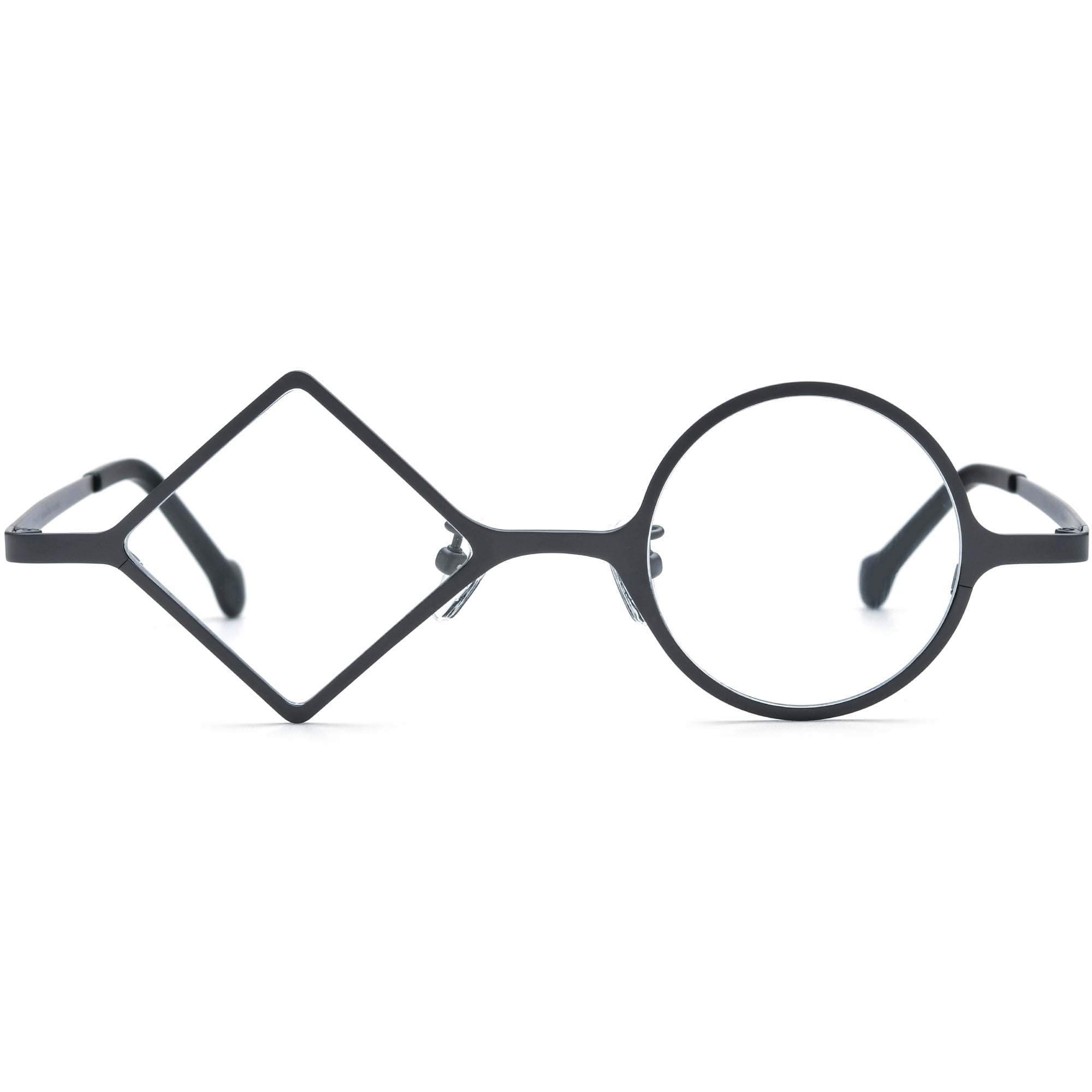

Another frame variation is the half-eye or reader frames. If any alternative is possible avoid using them. These frames are designed with wide bridges (nose pads spread wide apart) to sit low on the nose, so the wearer can look over the tops of them to see in the distance. With modern progressive designs being “user-friendly,” the need to “look-over” a lens is rarely necessary. Half-eye frames also split the lenses and create problematic edge thicknesses for the lab. In half-eyes with a full eyewire, the top of the lens will tend to pop out. In cord mounts, your patient will generally complain of the lens’s thickness. If you must make up a pair, use polycarbonate or high-index to flatten the lens profile and reduce thickness. Try instead to guide your patient towards a full eyewire frame.